Vapor Blast Machinery Specifications

Vapor Blast Manufacturing Company

3025 W. Atkinson Ave. Milwaukee, WI 53209

Ph. (414) 871-6500 Fax (414)-871-7683 Toll Free: 888-834-6500 E-Mail:sales@vaporblast.com

Copyright © 2011 Vapor Blast Manufacturing Co. All rights reserved.

Site Maintained By Blazing Mind Media

| ||||||

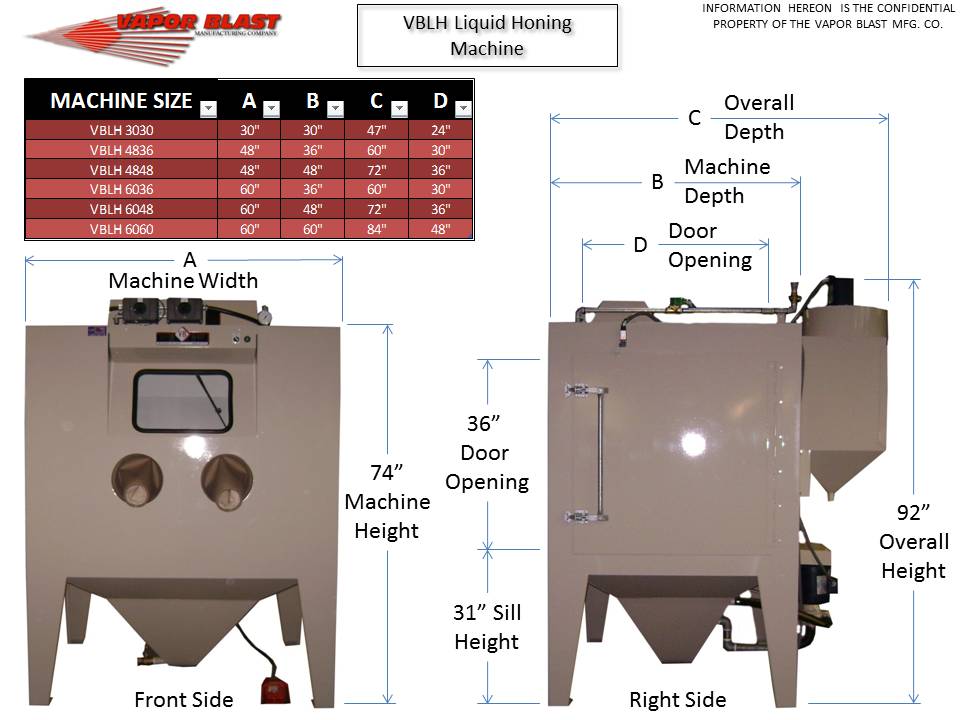

VBLH 3030 SERIES

Vapor Blast's Liquid Honer will turn your lab, tool room, machine/metal shop, or

production facility into a quality surface treatment center. Look at the advantages:

1.) Will reach crevices, fillets, edges, and corners in intricate parts that virtually impossible to clean,

deburr or polish by other means.

2.) Wet blast process using finer abrasive (up to 5,000 mesh) cleans parts without changing

tolerances. Will hold a 5 RMS.

3.) Vapor Blast Liquid Honing produces a very smooth surface with non-directional, finely etched, non-mirror (matte) finish.

4.) Peening with glass beads improves surface tensile strength by cold-working the metal.

What ever your surface treatment problem, Vapor Blast can solve it!

- Item:

VBLH 3030

VBLH 3030

- Item Name:

Vapor Blast Liquid Honing

Vapor Blast Liquid Honing

- Interior Dimensions:

30'' x 30'' x 40"

30'' x 30'' x 40"

- Overall Dimensions:

34" x 47" x 89"

34" x 47" x 89"

- Door Opening Height:

36"

36"

- Door Opening With:

24"

24"

- Standard Number Of Doors:

1

1

- Carbide Nozzle, Diameter:

1/2''

1/2''

- Stainless Steel Air Jet, Diameter:

1/4"

1/4"

- Slurry Pump Motor:

3/4 HP

3/4 HP

- Exhaust Fan Motor:

1/2 HP

1/2 HP

STANDARD FEATURES

* HEAVY-DUTY CABINET CONSTRUCTION, 10-12 GAGE MINIMUM STEEL WITH REINFORCING FRAME

HEAVY-DUTY CABINET CONSTRUCTION, 10-12 GAGE MINIMUM STEEL WITH REINFORCING FRAME

* NEMA I, NEC, 230/460 VOLT, 3 PHASE, 60 HERTZ, PRIMARY SOURCE WITH CONTROL TRANSFORMER TO 115

NEMA I, NEC, 230/460 VOLT, 3 PHASE, 60 HERTZ, PRIMARY SOURCE WITH CONTROL TRANSFORMER TO 115  VOLT, SINGLE PHASE, 60 HERTZ CIRCUIT

VOLT, SINGLE PHASE, 60 HERTZ CIRCUIT

* FILTERED EXHAUST SYSTEM WITH MANUAL SPRAY WASH SYSTEM AND 5” DIRECT DRIVE FAN ASSEMBLY

FILTERED EXHAUST SYSTEM WITH MANUAL SPRAY WASH SYSTEM AND 5” DIRECT DRIVE FAN ASSEMBLY

* VAPOR BLAST SLURRY PUMP ASSEMBLY SUPPLIES THE BLAST NOZZLE AND UNIFORMLY SUSPENDS

VAPOR BLAST SLURRY PUMP ASSEMBLY SUPPLIES THE BLAST NOZZLE AND UNIFORMLY SUSPENDS

* PUMP FLUSHING SYSTEM (FRESH WATER) WITH CONTROL VALVE

PUMP FLUSHING SYSTEM (FRESH WATER) WITH CONTROL VALVE

* FULL VIEW OPERATOR OBSERVATION WINDOW ... EASILY REPLACED SAFETY GLASS

FULL VIEW OPERATOR OBSERVATION WINDOW ... EASILY REPLACED SAFETY GLASS

* ELECTRIC WINDOW WIPER SYSTEM WITH ADJUSTABLE SPEED CONTROL; WINDOW RINSE NOZZLES ARE

ELECTRIC WINDOW WIPER SYSTEM WITH ADJUSTABLE SPEED CONTROL; WINDOW RINSE NOZZLES ARE

* HIGH OUTPUT FLUORESCENT CABINET LIGHT SYSTEM

HIGH OUTPUT FLUORESCENT CABINET LIGHT SYSTEM

* CABINET DOOR, RIGHT-HAND HINGED SWINGING ACTION. INTERLOCKED SAFETY SWITCH

CABINET DOOR, RIGHT-HAND HINGED SWINGING ACTION. INTERLOCKED SAFETY SWITCH

* OPERATOR ARMPORTS FITTED WITH WEAR RESISTANT RUBBER GAUNTLETS AND REPLACEABLE ATTACHED

OPERATOR ARMPORTS FITTED WITH WEAR RESISTANT RUBBER GAUNTLETS AND REPLACEABLE ATTACHED

RUBBER GLOVES

RUBBER GLOVES

* TYPE “S” BLAST GUN WITH 1/2” CARBIDE NOZZLE AND 1/4” STAINLESS STEEL AIR JET

TYPE “S” BLAST GUN WITH 1/2” CARBIDE NOZZLE AND 1/4” STAINLESS STEEL AIR JET

* SINGLE PROCESS CONTROL, VIA ELECTRIC FOOT SWITCH, ACTUATING SOLENOID CONTROLLED COMPRESSED

SINGLE PROCESS CONTROL, VIA ELECTRIC FOOT SWITCH, ACTUATING SOLENOID CONTROLLED COMPRESSED

* AIR GAGE; COMPRESSED AIR INTAKE FITTED WITH OSHA APPROVED AIR LOCK-OUT/BY-PASS VALVE

AIR GAGE; COMPRESSED AIR INTAKE FITTED WITH OSHA APPROVED AIR LOCK-OUT/BY-PASS VALVE

* PERFORATED METAL WORK PLATFORM (1,000-LB CAPACITY)

PERFORATED METAL WORK PLATFORM (1,000-LB CAPACITY)

* MACHINE SPECIFICATIONS IN COMPLIANCE WITH OSHA REGULATIONS

MACHINE SPECIFICATIONS IN COMPLIANCE WITH OSHA REGULATIONS

* MACHINE PAINTED WITH HIGH GRADE INDUSTRIAL ENAMEL (TAN)

MACHINE PAINTED WITH HIGH GRADE INDUSTRIAL ENAMEL (TAN)

MACHINE OPTIONS AND ACCESSORIES

* SETTLING TANK (PORTABLE INDEPENDENT UNIT)

SETTLING TANK (PORTABLE INDEPENDENT UNIT)

TANK INCLUDES WEIR SYSTEM TO SETTLE OUT AND COLLECT ABRASIVE. AN OVERFLOW DRAIN FITTING CAN BE CONNECTED TO BUYER’S SEWER TO DISCHARGE THE SEPARATED WATER. THIS TANK RECEIVES THE WATER DISCHARGED FROM THE CABINET WINDOW WASH.

* SLURRY EVACUATOR SYSTEM

SLURRY EVACUATOR SYSTEM

AN EFFICIENT SYSTEM THAT TOTALLY EVACUATES HOPPER SLURRY CONTENTS VIA AN ADJUSTABLE PNEUMATIC OPERATED DEVICE. THE SLURRY IS CONVEYED TO BUYER’S DISPOSAL CONTAINER WITH 8’ DISCHARGE LINE.

* SECOND SIDE LOADING DOOR ASSEMBLY

SECOND SIDE LOADING DOOR ASSEMBLY

HINGED SWINGING ACTION. INTERLOCKED SAFETY SWITCH PREVENTS MACHINE OPERATION WHEN DOOR IS OPENED.

* AUTOMATIC FILTER WASH SYSTEM

AUTOMATIC FILTER WASH SYSTEM

TIMER-CONTROLLED, AUTOMATIC SYSTEM OF FRESH WATER RINSE OF EXHAUST FILTER.

* STAINLESS STEEL CABINET AND HOPPER STRUCTURE

STAINLESS STEEL CABINET AND HOPPER STRUCTURE

WITH NON-FERROUS INTERIOR PIPING SYSTEM AND COATED WORKTABLE.

* OPTIONAL VERTICAL SLIDING CABINET DOOR ASSEMBLY

OPTIONAL VERTICAL SLIDING CABINET DOOR ASSEMBLY

FEATURINGDOUBLE PULLEY COUNTERBALANCED SYSTEM AND SELF-ACTIVATING SAFETY BRAKE. INTERLOCKED SAFETY SWITCH PREVENTS MACHINE OPERATION WHEN DOOR IS OPENED.

* INTEGRAL TURNTABLE – CABINET INTERIOR

INTEGRAL TURNTABLE – CABINET INTERIOR

HEAVY-DUTY, BALL BEARING SPINDLE MOUNTED, MANUAL ROTARY TURNTABLE ASSEMBLY.

* TUMBLING BARREL SYSTEM

TUMBLING BARREL SYSTEM

BARREL WITH LOCKING PARTS DOOR IS MOUNTED ON A HEAVY-DUTY HINGED BLAST CABINET DOOR

* VANE-CHEVRON SEPARATOR

VANE-CHEVRON SEPARATOR

EXHAUST SYSTEM WITH VANE-CHEVRON SEPARATOR. THIS STAINLESS STEEL ENTRAINMENT SEPARATOR EFFICIENTLY DROPS OUT MEDIA PARTICULATES AND WATER DROPLETS FROM THE EXHAUST GAS STREAM. THE RECOVERED EXHAUST PRODUCTS ARE RETURNED TO THE BLAST CABINET FOR RE-USE.

* CLOSED LOOP RINSE TANK & PUMP ASSEMBLY

CLOSED LOOP RINSE TANK & PUMP ASSEMBLY

FEATURING STAINLESS STEEL CONSTRUCTION AND DIAPHRAGM PUMP. TANK INCLUDES FOUR (4) COMPARTMENTS WITH THREE (3) REMOVABLE BAFFLES TO SETTLE OUT AND COLLECT ABRASIVE

* 4-STAGE EXHAUST SYSTEMS

4-STAGE EXHAUST SYSTEMS

* EXHAUST SYSTEM MONITOR

EXHAUST SYSTEM MONITOR

* HOUR METER FOR BLAST TIME

HOUR METER FOR BLAST TIME

* ADVANCED AUTOMATION

ADVANCED AUTOMATION

ADVANCED AUTOMATION USING: SKEWED ROLLER, PINCHED ROLLER, CONVEYORS, INLINE CONVEYORS, INDEXING TURNTABLES, ROTARY TUMBLING BARRELS, ROTARY SPINDLES, GUN OSCILLATION, CARRIAGE SHUTTLE

LIQUID HONING UNITS: BLAST/ WASH/ RINSE/ DRY

FROM SIMPLE TO COMPLEX SYSTEMS